What should be done for a battery to be efficient and long-lasting?

A battery behaves just like a human in many ways. He feels the affection you show, and the more care you give, the more he will give back to you. It's almost as if he has feelings, and the better he is treated, the more he gives back. Of course, there are exceptions to this, as all raising parents will know; The generosity shown may not always yield the expected results.

To take good care of batteries, you need to know the basic requirements of a battery, which is not a subject taught in schools.

Just as a person's life span cannot be predicted when he is born, nothing can be said for certain about the lifetime of batteries. Some types of battery packs last a long time, while others become unusable after a short time. Incorrect charging, charging the battery for discharge, and exposure to heat are the biggest enemies of batteries. While there are ways to protect a battery, it is not always possible to achieve the ideal state. We will tell you the ways to get the most efficiency from your batteries.

Resetting a battery

Not all rechargeable batteries provide the capacity stated on them when new and require a formatting process. While this rule applies to most battery systems, lithium battery manufacturers oppose it. They say that lithium is ready for use and does not require a separate process to be ready for use. While this seems to be true, some users have reported some increases in capacity after a long wait.

"So what's the difference between formatting and resetting"? If you ask: Both are concepts that refer to capacities that have not reached the optimum level and can be improved with the charging cycle. The formatting process is something that occurs naturally when the battery is in its life cycle and is a complement to the initial manufacturing process. A typical example of this is lead and nickel-based batteries whose capacity develops with use. On the other hand, priming is a cycle improvement process applied to increase the performance of the battery during use or after a long standby time. The reset process is mostly applied to nickel-based batteries.

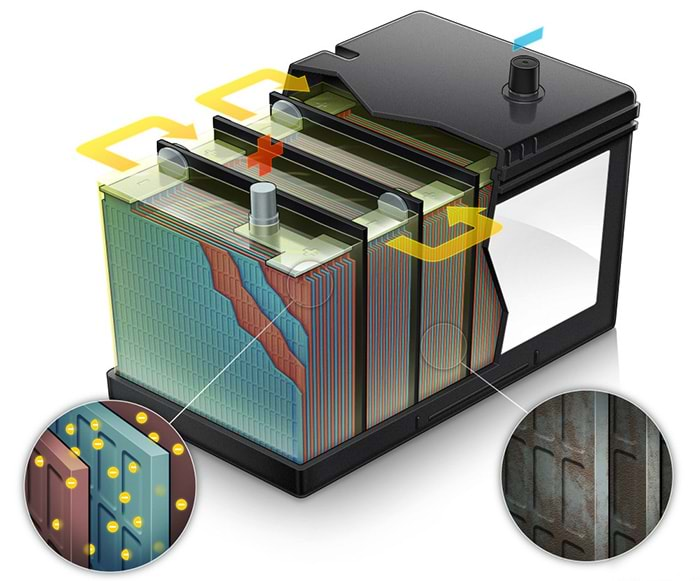

Lead acid batteries

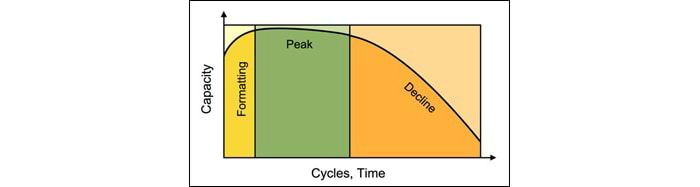

Formatting a lead acid type battery is done by charging followed by a charge-discharge cycle. This process is done at the factory and is completed by users in the field as part of daily use. Experts recommend not loading new battery for heavy-duty work that will lead to high energy discharge at first use. Instead, they suggest using the battery with a more even and gradual discharge. Just like an athlete training to lift weights or run long distances. Of course, this may not be possible for the starter battery in a car or for other uses. Lead acid batteries typically reach full potential capacity after 50 to 100 cycles. In the picture below you can see the life cycle of a lead acid-type battery.

A new lead acid battery may not be fully formatted and will achieve full efficiency after 50 or more cycles. Formatting takes place during use; Artificially charging and discharging the battery outside of use is not recommended as this will unnecessarily wear out the battery.

Deep-cycle batteries when new are about 85 percent capacity and will approach or reach 100 when fully formatted. There are also some outliers where levels as low as 65 percent are observed when tested with a battery meter. The question may arise, “can these low-efficiency batteries regain power when formatted and compete with higher-efficiency batteries?” An experienced battery expert answers this question by saying, “These batteries will get better somehow, but they will be the first to fail.” The function of a starter battery is to start the engine by providing high-intensity current, and this quality is present in the starter battery from the start, and it does not require formatting or resetting. What surprises many bikers is that even if the capacity of the starter battery is reduced by 30 percent, it can still start the engine. However, if the drop is greater, the driver may not be able to start the vehicle one morning and may be stranded.

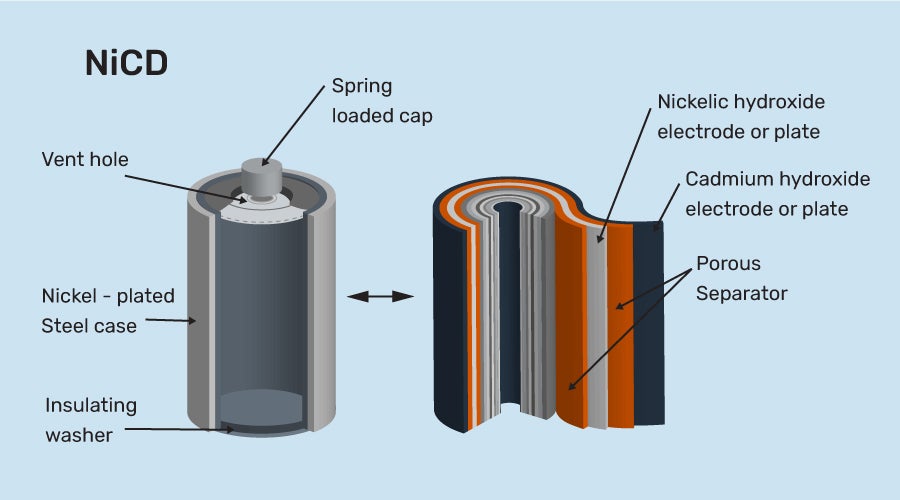

Nickel-based batteries

Manufacturers recommend charging nickel-based batteries slowly and evenly for 16-24 hours when new or after a long standby time. This process allows the cells in the battery to adapt to each other and reach an equal charge level. Slow charging also helps to remove dry spots that may form on the separator due to the effect of gravity by re-dispersing the electrolyte.

From the factory, nickel-based batteries are not always fully formatted. With normal use or with the battery analyzer, charging/discharging several times completes the formatting process. The number of cycles required to achieve full capacity differs from manufacturer to manufacturer. Quality batteries fulfill their qualifications after 5-7 cycles, while some low-cost alternatives can reach acceptable capacity levels after 50 or more cycles.

Lack of format is a problem when the user expects a battery to operate at full capacity right out of the packaging. Organizations that use batteries for certain missions and critical applications must verify battery performance with regular charge/discharge as part of their quality control process. The “prime” program of Cadex systems, which performs automatic battery analysis, performs as many charge/discharge cycles as necessary to reach full capacity.

Cycling also restores lost capacity if a nickel-based battery has not been used for several months. The standby time, the state of charge, and the temperature in which the battery is stored are the factors that determine the ease with which the battery can be returned to its previous capacity. The longer the storage time and the higher the temperature, the greater the number of cycles required to return the battery to full capacity.